- Payoff stands: Revolving turntables equipped with brake tensioners for wire formers and spools, overhead coil openers, pintle-type payoff for coils, and motorized payoff systems for spools.

- Open Earth Furnace or Lead Bath Furnace featuring electrical heating or combustion systems using Natural Gas, LDO, or FO, complete with a top cover and recuperator for energy conservation.

- An online fumeless pickling system with water curtains designed to prevent any acid fumes from escaping the pickling area.

- Wires move in a straight path with reduced tension and interact with energizing acid flowing counter to the wire, followed by a triple-stage water wash system.

- An intermediate wiping system between chambers to minimize excessive fluid carryover from one chamber to another.

- Vertical gland/seal-less pumps ensuring zero downtime since no seal replacements or routine maintenance are necessary.

- A stainless-steel SS-316 fabricated flux tank with flue gas heating and a temperature control system aimed at energy efficiency and consistent coating. Options include dipping type or a straight path flux pumping system.

- A flux dryer before the entry into the galvanizing bath hot plate assembly enables rapid drying of the flux, utilizing heating from the flue gases of the zinc bath furnace, as rising energy costs make conservation a critical focus in today’s plants.

- The zinc bath furnace features a structural steel frame fully lined with multiple layers of ceramic refractory, ensuring reliability and durability due to high-quality materials.

- The zinc tank is constructed from low carbon, low silicon steel plate, with 90º bends welded using specialized electrodes and thoroughly ultrasonically tested for internal cracks, with options available for light, medium, and heavy coatings.

- Zinc coating control can be achieved through pad wiping, spring wiping for low and medium coatings, and vertical charcoal or nitrogen wiping for heavy coatings.

- Finally, the wire is coiled in finishing take-ups, with ASSOMAC offering various options based on coil weight requirements, ranging from 25 kg to 1000 kg. Our manufacturing program includes horizontal side winder take-ups, vertical drop coilers with or without pattern lay, and strip take-ups.

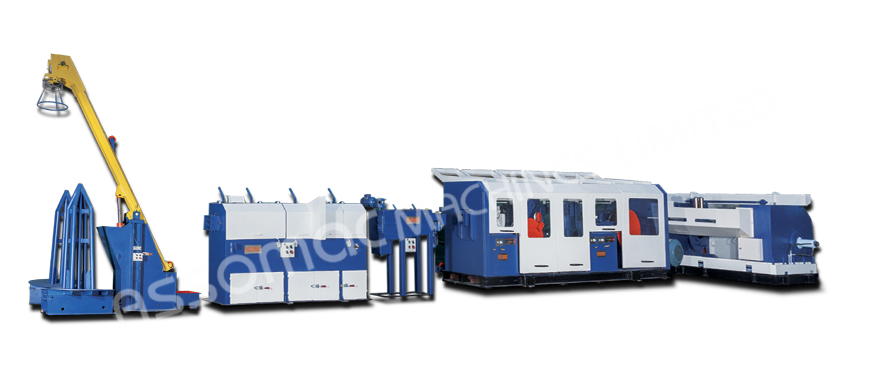

Galvanized Wire Plant

Overview

The ASSOMAC group offers its clients the latest, most cost-effective, efficient, and high-speed lines for wire galvanizing. Our range of equipment includes drawing lines, flattening mills, and comprehensive galvanizing lines featuring vertical drop coilers, horizontal side winder take-ups, or strip take-ups. Through our excellence in design, engineering, manufacturing, and service, we provide the most relevant technology for galvanizing low and high carbon steel wires.

ASSOMAC has established itself as a leader in delivering turnkey projects for the wire industry, and we aim to sustain this position by offering dependable equipment and services to our customers around the globe.