Material :

Material should be of fusion quality. Low carbon & un-alloyed steel is highly recommended. However, commercial quality wires available in market can also be used up to a certain extent.

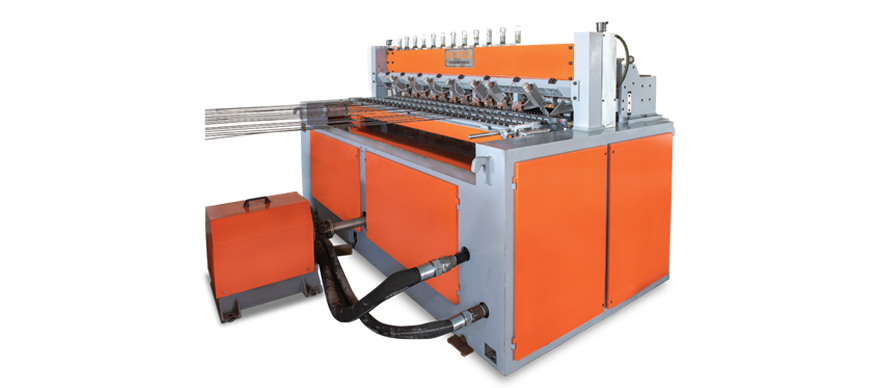

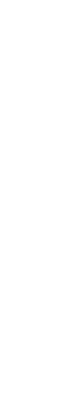

Working Procedure :

The line wires are pulled from coils, cross wires are pre-straightened and cut to length, which are then fed into the welding stations one after the other automatically.

Line wires are pulled through advance carriage with a predetermined length (distance between cross wire) and cross wire are dropped by a highly reliable system of magnets. Fusion of line wire with cross wire is done by resistance welding transformers which are controlled by micro-processor based digital welding controller